Tray dryers

Practical Action

in order to maximise output 24 hour working is recommended

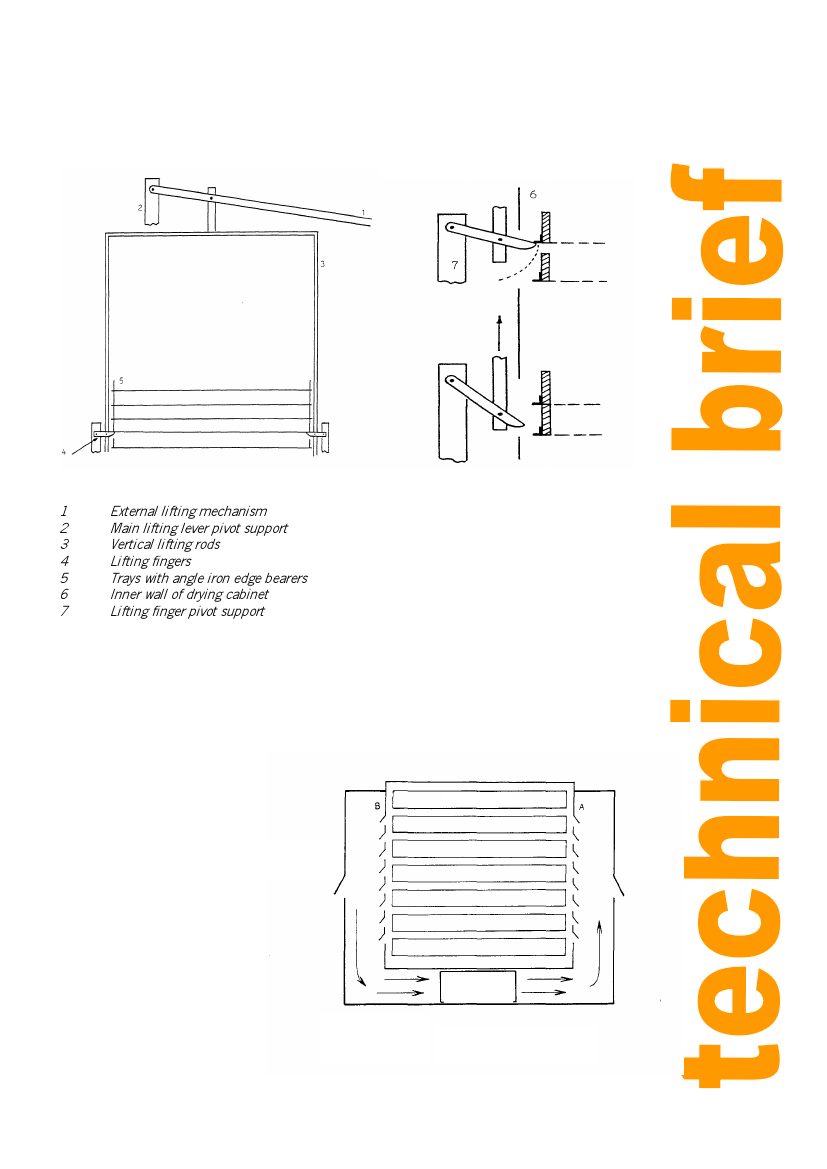

Typical semi-continuous dryers are shown in Figure 3, which shows the lifting mechanism and the

gap above the lowest tray that is ready for removal.

Detail of lifting fingers

1 External lifting mechanism

2 Main lifting lever pivot support

3 Vertical lifting rods

4 Lifting fingers

5 Trays with angle iron edge bearers

6 Inner wall of drying cabinet

7 Lifting finger pivot support

Figure 3: Semi-continuous dryers

Cross flow chambers. Although Practical Action has not developed this system it is considered worth

mentioning in this short brief. In this chamber the air is blown, through a series of louvers, directly

across the trays and then re-circulated over the heater. In the early stages of drying, when a lot of

water is being removed, a high proportion of the air is vented to an exit and replaced by fresh air. As

drying proceeds the proportion of vented air is reduced. At the end of the drying cycle no air is

vented. This system then

overcomes the problems

associated with batch and

semi-continuous cabinets in

Product trays

that:

labour costs are low as it

works like a batch dryer

all the trays dry at the same

Wet air

exhaust vent

Dry air

inlet

rate

fuel efficiency is

maximised.

Cross flow systems are

however, technically more

complex and require automatic

humidity sensors to control the

percentage of air vented during

the drying cycle.

Heating fan

A – Inlet Vent

B – Exhaust Vents

Opening/Closing controlled by

humidistat

Figure 4: Schematic diagram of a cross flow cabinet

3